NEW! HAAS UMC-750 COVER AND MIST COLLECTOR PACKAGE

|

We are excited to offer our new top cover for the HAAS UMC-750 machines. These machines come with no top enclosure allowing chips and coolant mist to escape, making a mess of your shop. Our easy to install Top Cover and Mist Collector is the perfect package to keep everything inside your machine!

Please contact us for more information. *HAAS is a registered trademark owned and licensed by Haas Automation, Inc. |

Cutting Tool Engineering Magazine Case Study

|

Cutting Tool Engineering Magazine has done a very nice case study on our VariFlow coolant system, in the January edition of their magazine. It can be found on page 88, or if you do not get the publication, it can be found here:

|

New line of Mist Collectors

We are excited to introduce our new line of Multi-Stage oil mist collectors. We offer sizes 400, 600, 800, 1100, 1400 and 2000 CFM.

|

Introducing our new Coolant Filtration System, the "CycloFlow"

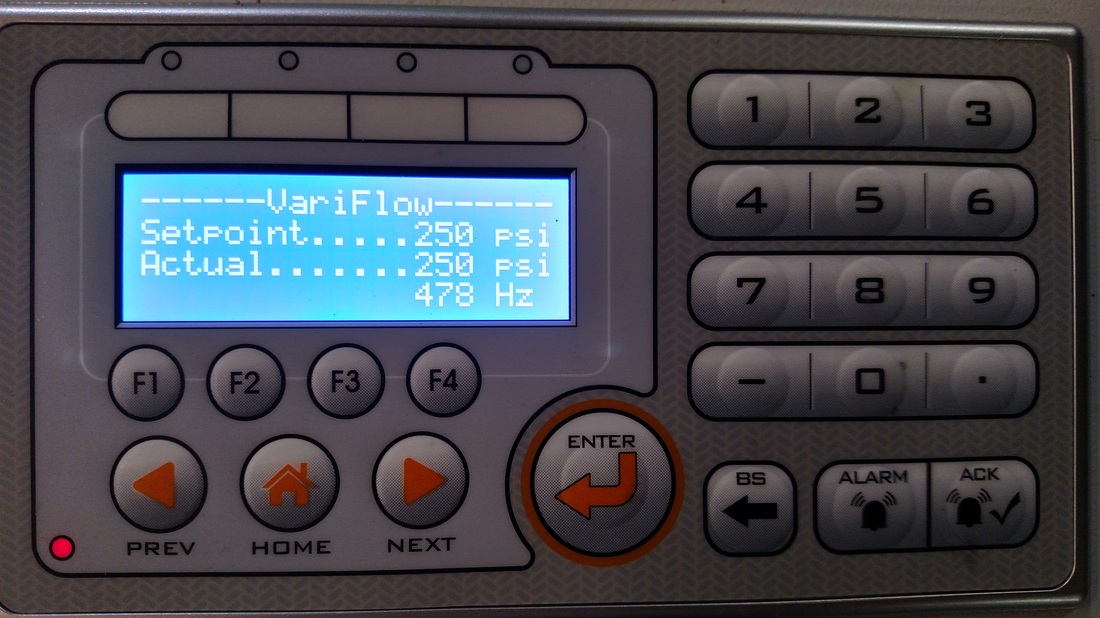

Introducing our new Adaptive Pressure Control

Our new Adaptive Pressure Control is a digital HMI that gives the operator full control over the high pressure coolant system. A very specific pressure can be set using the digital keypad and the system dynamically varies the speed of the pump to output the set pressure. This means a constant pressure can be achieved for different tools without using a pressure relief valve to constantly dump back to the tank. The benefits include; energy efficiency, less foaming, more precise control and longer system life.

ICS system being used in a robotic work cell

This is a video of our systems being used in a high volume production plant in Canada. These custom built coolant systems are used in a robotic work cell to clean parts after machining. Our customer had a very specific need and we were able to meet their needs with a custom system which is now called the DT58. This system has an on-board tank, diaphragm pump, variable pressure control and solenoid valve. This unit runs like a hydraulic system, circulating constantly back to its own tank; when pressure is needed the solenoid valve opens and provides virtually instant pressure to the machine.

Video courtesy of Vengor Automation, Inc.

Video courtesy of Vengor Automation, Inc.